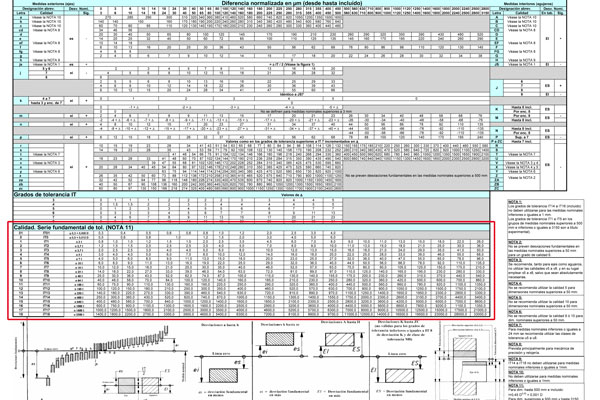

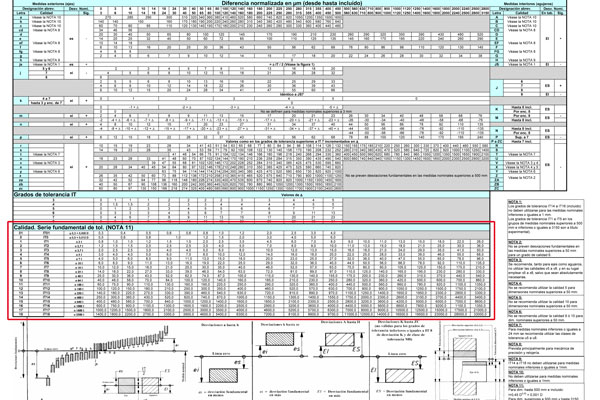

Hole 'A' and shaft 'a' have the largest fundamental deviations, the hole being positive and the shaft being negative. The fundamental deviation of tolerance zone from the basic size is designated by capital letters A, B, C.Z is provided for holes and small letters a, b, c.z is provided for shafts. ) shall not be used for basic sizes less than or equal to 1 mm. 3) Standard tolerance grades IT14 to IT18 (incl. 2) Values for standard tolerance grades IT1 to IT5 (incl.) for basic sizes over 500 mm are included for experimental use. 1) Values for standard tolerance grades IT01 and IT0 for basic sizes less than or equal to 500 mm are given in IS0 286-1, annex A, table 5. Using the designated International Tolerance Grade formula, the IT Grade required or typical to produce the part feature is assigned.įor example, plastic injection molding is determined to have an IT Grade of 13 and a part needs an IT Grade of 5, engineering and design should consider an alternative and more capable manufacturing process to produce the part and feature. When designing a part and specifying mechanical tolerances, engineering or design will determine size and location for a particular feature.

Hole 'A' and shaft 'a' have the largest fundamental deviations, the hole being positive and the shaft being negative. The fundamental deviation of tolerance zone from the basic size is designated by capital letters A, B, C.Z is provided for holes and small letters a, b, c.z is provided for shafts. ) shall not be used for basic sizes less than or equal to 1 mm. 3) Standard tolerance grades IT14 to IT18 (incl. 2) Values for standard tolerance grades IT1 to IT5 (incl.) for basic sizes over 500 mm are included for experimental use. 1) Values for standard tolerance grades IT01 and IT0 for basic sizes less than or equal to 500 mm are given in IS0 286-1, annex A, table 5. Using the designated International Tolerance Grade formula, the IT Grade required or typical to produce the part feature is assigned.įor example, plastic injection molding is determined to have an IT Grade of 13 and a part needs an IT Grade of 5, engineering and design should consider an alternative and more capable manufacturing process to produce the part and feature. When designing a part and specifying mechanical tolerances, engineering or design will determine size and location for a particular feature.

IT grades provide guidance for typical manufacturing process capability or how precise one can except manufacture of a particular features or features. Application: Most manufacturing processes have an IT Grade designated for specification. International Tolerance grades are calculated as following: Where: T = Tolerance in micrometers D = Geometric mean dimension in millimeters ITG = IT Grade, a positive integer.

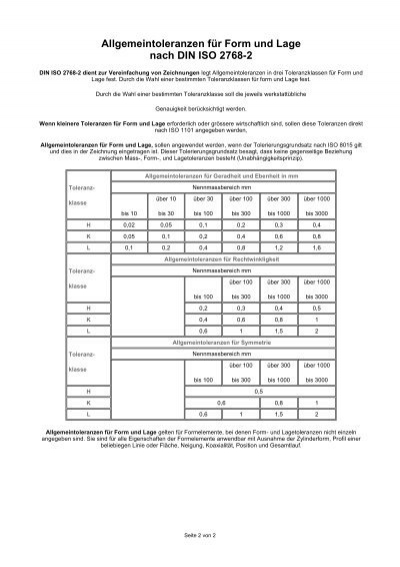

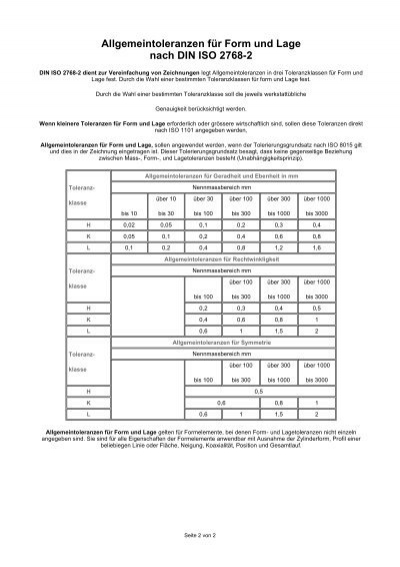

This mechanical tolerance grade specifies tolerances with associated manufacturing processes for a given dimension. International Tolerance (IT) Grades Table Chart International Tolerance (IT) Grades table reference ISO 286. For new designs only the general tolerance according to DIN ISO 2768-1. ISO 2768 – m or general tolerance ISO 2768 – m. Q – If a basic dimension does not show a specific tolerance what tolerance should be applied? ISO Tolerances According to DIN ISO. Question about a basic dimension without a specific tolerance.

The latest DIN standard sheet version applies to all parts made to DIN standards. ISO 2768 and derivative geometrical tolerance standards are. The following are general geometrical tolerances per.

0 kommentar(er)

0 kommentar(er)